Laser

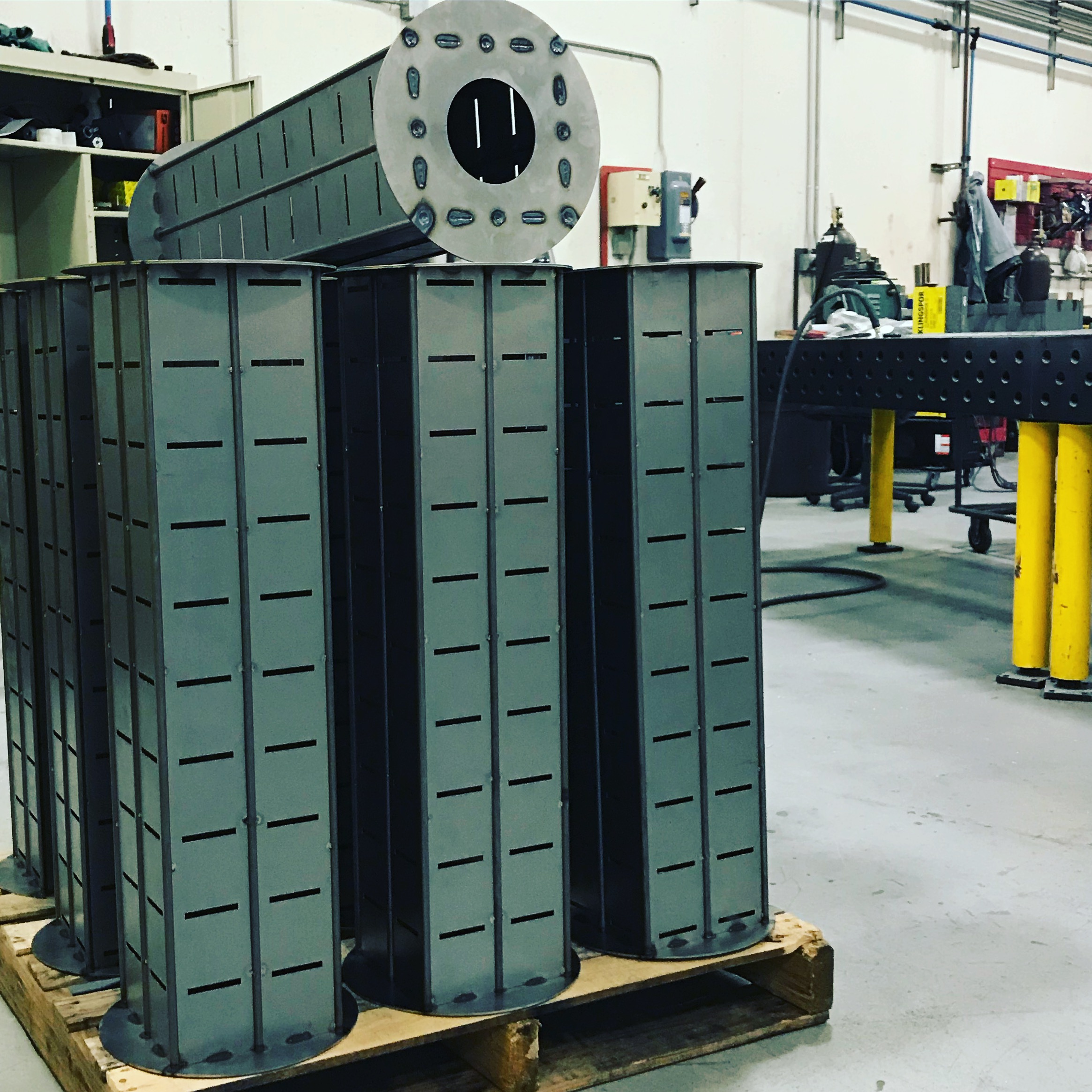

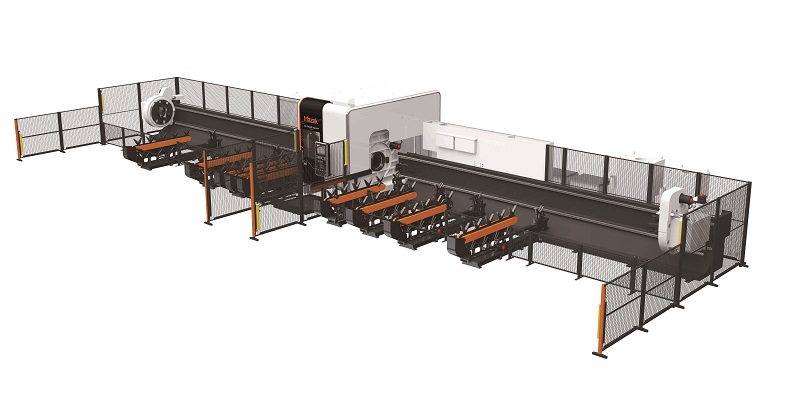

Mild Steel, Tool Steel, Aluminum, Stainless Steel, Brass, Copper materials. Table size is 60"x 120", up to 1" mild steel and ¾" alum plate can be cut. The laser is attached to an Eight Shelf Automation Tower for continuous production without stopping for new material change over.

| Equipment | 6000kw Fiber Laser, 4000Kw CO2 Laser | ||||

|---|---|---|---|---|---|

| Materials | Mild Steel, Stainless steel, Aluminum, Copper, Brass, Acrylic, Tool Steel, Titanium, Spring Steel | ||||

| Sheet size |

|

||||

| Thickness Range |

|

||||

| Tolerances |

|

||||

| Automation |

|

||||

| File formats Required |

|

||||

| Nesting | We use a program that nests the parts for our machines to get best material usage and fastest cut times. | ||||

| After Cutting Process available |

|

||||

| Surface Etching | Fiber can etch numbers and logos. Works best on Stainless, can be done on steel and alum to differing degrees. |

-

Laser Cutting etc...

Browse the gallery to see some examples of our laser and Waterjet cutting.

Cutting is the foundation of any fabrication project. TMS has the latest laser equipment to make your sheet and pla...

-

Right Now !!

Here is the work that is in progress or has just completed production and is ready to ship.

Laser Cutting

Perfect Metal Parts

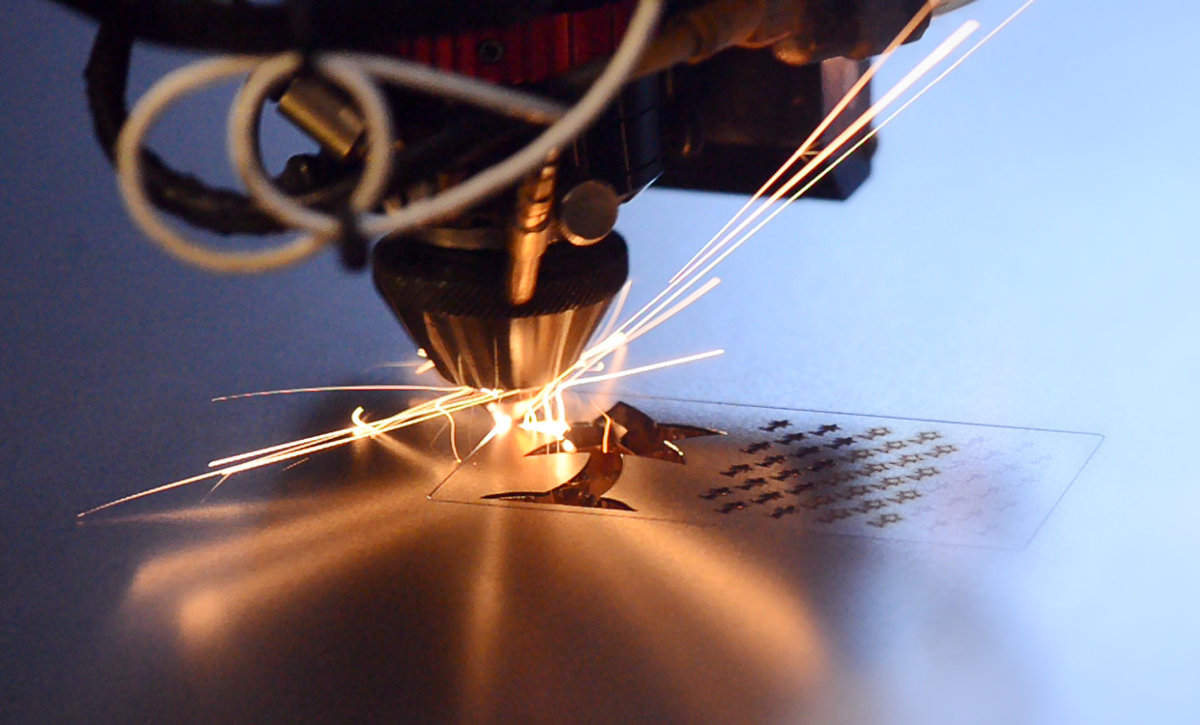

Laser cutting is often the most effective process for cutting plate or sheet metal for sheet metal fabrication, including carbon steel, stainless steel, aluminum, copper and many other alloys. TMS's laser cutting processes incorporate off-line programming and part nesting for material maximization. Our 6KW Mitsubishi Fiber Laser provides, speed, precision, flexibility and value for our customers. Fast set-up time is perfect for one piece or long runs.

Laser cutting is a highly accurate means of cutting metal. Laser is best suited to cutting steel, aluminum and some alloys. For sheet metal and thinner steel, laser is the best choice; it can cut faster and more accurate than most other forms of cutting. The speed of the laser helps keep cost down as most shops charge by the hour. In addition our laser is equipped with an 8 shelf auto loader which allows the machine to run unattended for longer run jobs. This helps keeps handling cost to a minimum and helps reduce scrap.

The effects on the work piece materials are rather minimal due to the small zone of metal affected by the laser beam. However, the effects are due to the high temperature of the laser that change the hardness and the creation of a narrow heat-affected zone.