For tubing, we use CNC bending equipment that can accommodate mild steel, stainless and aluminum tubing, with sizes ranging up to 6" O.D.

Our premier tube bender is our all Electric StarBender from ITEC. It is a 3D Freeform bender with interpolation. It has a capicity of 14gauge, 2 inch mild steel. This means it has the ability to bend tubes in one set-up unlike most conventional Right/Left benders and also gives tube rolling like capabilities to a mandrel bender. This ability to freeform means we can help you design more complex tube parts without having to add extra tooling costs and cut down on material usage. The StarBend CNC electric bender allows us to automatically achieve highly accurate radii. We are able to take parts from our tube laser and form them on the Star Bender with just a few clicks of the mouse. These features give you the ability to design more creatively and with more imagination.

For larger tube diameters we have a CNC Eaton Leonard bender which can bend up to 3" tube. This machine is a double stack unit which is used for heavier gauge tube and larger diameters. It is geared toward more structural type parts.

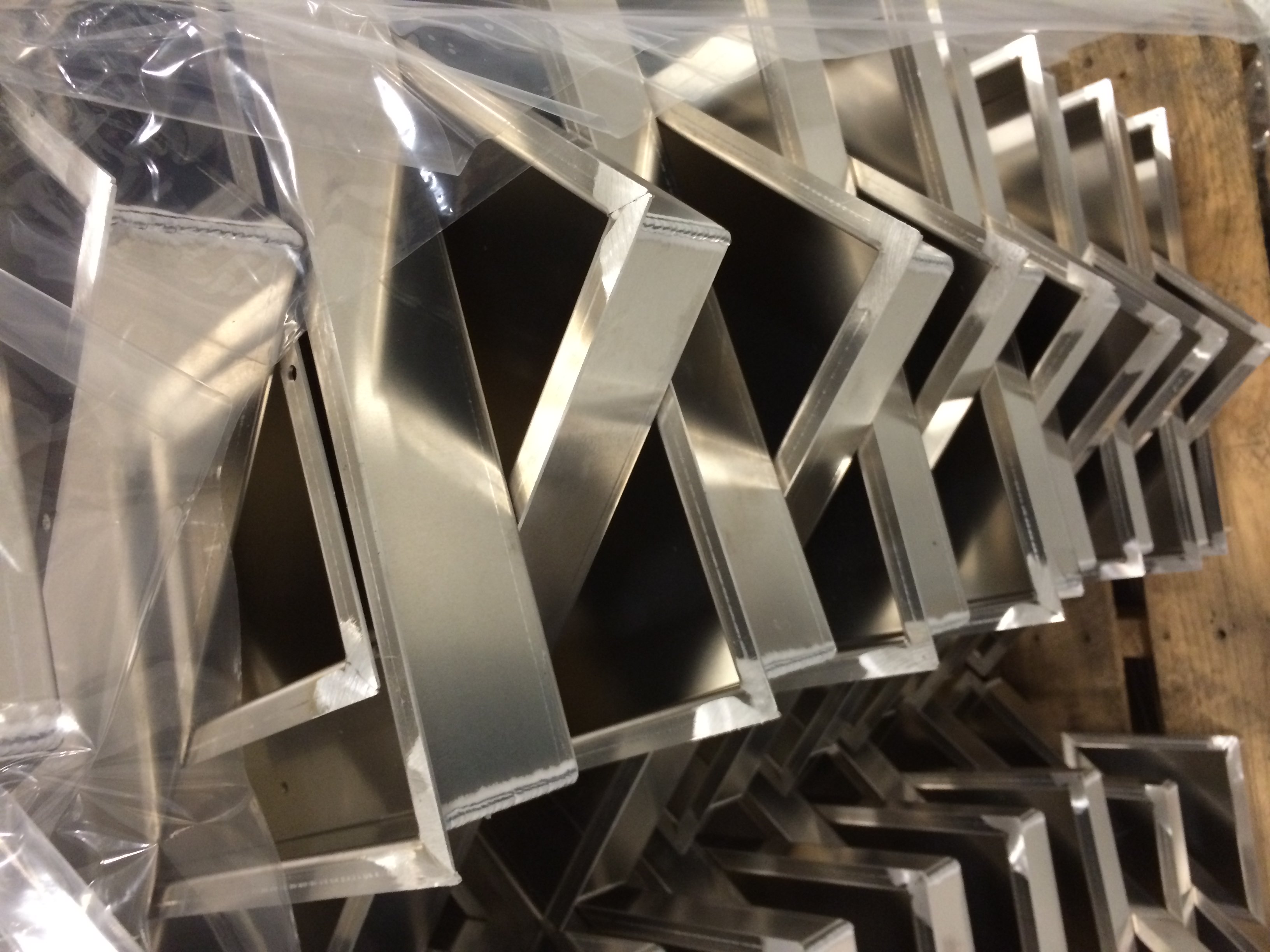

Our tube rolling machines are used for rolling tube at more sweeping angles, or shapes into coils, circles or large arcs using a wide variety of materials. We have two Arkus CNC Roll Benders from Switzerland. These are the best machines on themarket and are highly accurate. We can roll square, rectangular, round, obround and angle material with these machines. These machines allow us to do many difficult projects such as ellipses and compound radius rolling. Between the two machines we are capable of rolling round tubing up to 4” round and 6” square.

We also do swaging. This process is done mostly with aluminum, copper or thin wall steel. We take tubing and reduce the outside diameter down to a specific diameter. Cold swaging is relatively quick, inexpensive and chip less. We use a Finn-Power P32 VS23 swaging machine that handles 4mm-87mm tube.